Choosing the best 3D modeling software for your project can be difficult. This article will help you compare Onshape vs SolidWorks. They are two extremely comprehensive and robust 3D modeling packages that can help you with everything from visualization and simulation to prototype and production on the job, with Onshape being a cloud-based software and Solidworks being a local/offline-based software.

Onshape

Contents

Onshape is a cloud-based software as a service (SaaS) computer-aided design company founded in 2012 by two former SOLIDWORKS CEOs. Onshape is a data management and collaboration software. It was one of the first CAD product development platforms to use the software as a service (SaaS). As it is delivered as a SaaS model, Onshape does not require downloads, installations, or updates. All you need to use Onshape is a compatible web browser and an internet connection because all of its features are accessible via the internet. It is one of the software’s most notable features. Onshape works with iOS, Android, Linux, OSX (Mac), and Windows. Given its creators, you would probably expect this software to have impressive features. Onshape’s elements are divided into the following categories: CAD, data management, collaboration, security and audit controls, analytics and reporting, and integration and partners.

Onshape’s CAD features allow you to create individual parts and assemblies of various elements. You can also create detailed 2D working drawings with dimensions, annotations, tables, data, and part lists. You can also import and export various industry file formats with these features.

Onshape can also be referred to as MCAD (mechanical computer-aided design) software and can be used in industries to produce automated machinery, 3D printing, and consumer electronics. It includes a plethora of user-friendly tools for expediting the work process. Onshape is an excellent tool for collaboration. Aside from being a versatile piece of software, it also assists you with project management. It also has a significant manufacturing process and real-time analysis. The software is well-known and is used in over 170 countries.

SolidWorks

SolidWorks is Dassault’s most well-known 3D design application for industrial and mechanical models. SolidWorks was introduced as the flagship product of its parent company, SolidWorks Corporation, in November 1995. Users can use Solidworks to create mechanical parts, complex machinery assemblies, and welding structures, among other things. As the name implies, SolidWorks is a solid modeling application. Users of SolidWorks can create models, components, and assemblies using a parametric function-based method. SolidWorks models typically begin with a 2D drawing before being extruded in 3D using various SolidWorks tools. SolidWorks is capable of handling large assemblies of any size. Thanks to the latest SolidWorks upgrades, users can now work with larger bodies and modify them in large design review mode. SolidWorks is a powerful solid modeling CAD software for design, engineering, and manufacturing. This software includes many professional-grade tools for the various stages of product development. 3D CAD, simulation, visualization, electrical design, collaboration, product data management, product configuration, and technical communication are the features of SolidWorks.

SolidWorks’ simple 3D design and modeling features enable you to conceptualize, create, validate, and transform your ideas into product designs. These features will allow you to develop 3D models from 2D sketches using parametric modeling. SolidWorks has the tools you need to create a part, an assembly, or a working drawing, no matter how complex the design.

Onshape vs SolidWorks

Onshape vs Solid Works can be compared to Microsoft Office and Google G Suite, with Solidworks being comparable to Office and Onshape being similar to G Suite. Solidworks, like Office, is primarily a desktop application that is installed on your computer and is frequently regarded as a more powerful tool when compared to cloud-based alternatives (like G Suite). Onshape, like G Suite, is a cloud-based application that requires an internet connection to run through a browser but has the inherent advantages of being on a shared access platform. As a result, the following criteria will be used to distinguish between this two powerful 2D and 3D professional CAD software.

Onshape vs SolidWorks: Similarities in Functions and Features

- Modeling tools

SolidWorks is a wonderful and user-friendly piece of software. It allows you to accelerate the modeling process. The software will enable you to create complex objects and assemblies quickly. You can model any shape and size you want. You can connect your 2D drawings and 3D models with the manufacturing documents, which allows you to update all changes made to the drawings.

Before you begin modeling, Onshape allows you to create and save documents in the software’s database. It’s a great option because it will enable you to keep all of your project’s sketches, parts, and assemblies in one folder. You can also save non-CAD files, PDF files, and images. To later compose bodies, you must first begin modeling parts. Onshape users use the Part Studio tabs to start modeling these parts.

This tab contains sketching tools to assist you in creating your first sketch, after which you must use feature tools to create a solid object. It is worth noting that each studio contains geometrically related parts.

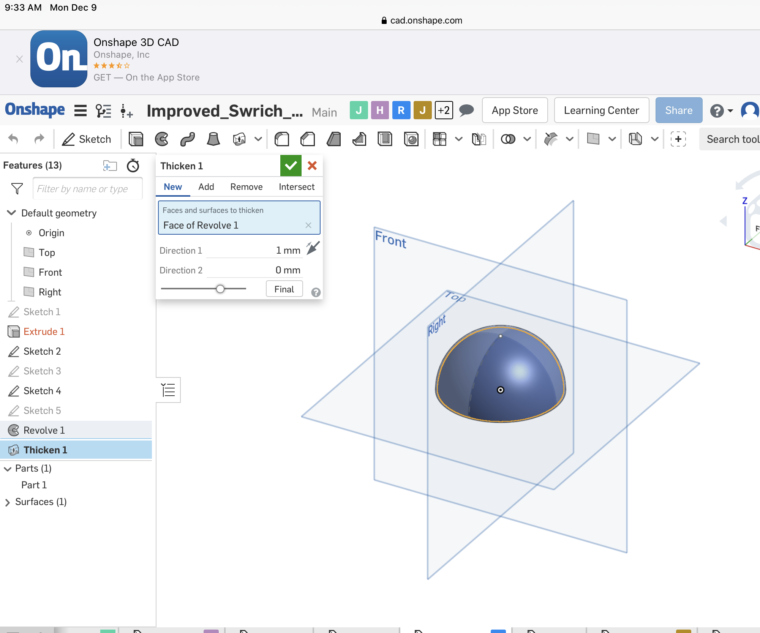

- Extrude

Boss-extrudes, the most basic function for adding material in a CAD program, differ slightly between these two programs. Both packages have fairly comprehensive extrude options for ending in two directions with a face, vertex, draft, and so on, but Onshape has built the surface extrude into their more specialized tools. Solidworks can perform a thin-extrude (creating a 3D boss from an unclosed sketch), whereas Onshape does not. In Onshape, the same process as a thin-extrude requires two in-series operations: surface-extrude and thicken.

- Measure

The Measure tool is constantly in use and is truly indispensable. Solidworks’ Measure tool is potent, allowing you to select points, edges, faces, completely random points in space, section view edges and ends, and so on. Onshape lacks some functionality, and getting a tricky dimension in some random location in a complicated part or assembly can be difficult.

Onshape vs SolidWorks: Differences in Functions and Features

- Installation

Onshape does not require any installation. Within 5 minutes of signing up, it’s in the cloud and in your browser. It was not particularly difficult to install SolidWorks. Insert your disk, use the download link, and then follow the onscreen instructions to install the software. The installation time depends on your system.

- Collaboration

Onshape allows multiple users to edit designs at the same time and will enable users to see changes in real-time. Its strong granular security allows or disallows view, edit, and export functions, giving you complete control over your intellectual property even when working with external stakeholders and partners. Its simple user interface is ideal for non-users or non-technical people who want to view designs or find information without spending hours learning how to navigate a CAD system.

Solidworks’ collaboration mechanism is archaic, relying on a series of plugins and connectors to provide visibility. The approach is limited in its applicability and makes it difficult for people, mainly external stakeholders, to stay informed about a project or design.

Onshape uses a modern approach to collaboration, with tools that make it simple for even non-technical users.

Onshape vs SolidWorks: Areas of application and specific users

Onshape focuses on MCAD (Mechanical Computer-Aided Design), so its primary users are mechanical engineers, designers, and manufacturing industries. The SaaS model of Onshape and its excellent collaboration and data management features make it the preferred choice of designers who work in a team or with customers.

SolidWorks’ extensive capabilities cover all aspects of the product development process, making it useful in various industries and professions. Any industry that requires manufacturing or product creation would benefit significantly from SolidWorks. SolidWorks is currently used by millions of people in hundreds of thousands of businesses worldwide. Manufacturing, aerospace, automotive, robotics, construction, oil and gas, agriculture, and many other industries use the software extensively. Electrical engineers and technicians also use SolidWorks to design and analyze complex electrical systems.

Conclusion

Onshape vs Solidworks? Which one is best for you? Both CAD programs in this comparison have their advantages and disadvantages. While Onshape may be a better tool for multiple CAD users to work with, it goes beyond simple CAD to all product design requirements, including product data, collaboration, and analytics; SolidWorks offers additional tools for project simulation, fluid mechanics management, and the unique ability to estimate the cost of constructing a project in real-time.